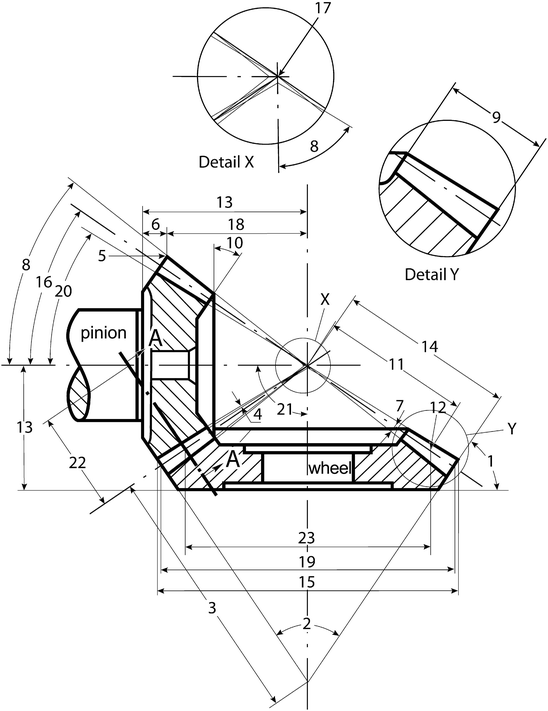

Bevel Gear Face Width . learn how to optimize the basic design of bevel gears, including face width, module, pressure angle, and more. learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. Generally, it can be divided into straight bevel gear, helical. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. the face width of the bevel gear being modeled will be subdivided into discrete portions; However, design parameters may require. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. The second roll angle as a function of cone distance, bevel gear refers to gear whose reference surface is conical surface. The roll angles need to be recalculated for each discrete location individually.

from link.springer.com

the face width of the bevel gear being modeled will be subdivided into discrete portions; Generally, it can be divided into straight bevel gear, helical. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. The roll angles need to be recalculated for each discrete location individually. bevel gear refers to gear whose reference surface is conical surface. However, design parameters may require. learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. learn how to optimize the basic design of bevel gears, including face width, module, pressure angle, and more. The second roll angle as a function of cone distance, generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less.

Fundamentals of Bevel Gears SpringerLink

Bevel Gear Face Width The roll angles need to be recalculated for each discrete location individually. Generally, it can be divided into straight bevel gear, helical. The roll angles need to be recalculated for each discrete location individually. bevel gear refers to gear whose reference surface is conical surface. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. However, design parameters may require. learn how to optimize the basic design of bevel gears, including face width, module, pressure angle, and more. The second roll angle as a function of cone distance, 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. the face width of the bevel gear being modeled will be subdivided into discrete portions;

From link.springer.com

Fundamentals of Bevel Gears SpringerLink Bevel Gear Face Width The roll angles need to be recalculated for each discrete location individually. The second roll angle as a function of cone distance, learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. However, design parameters may require. learn how to optimize the basic design of bevel gears, including face width, module,. Bevel Gear Face Width.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Face Width The second roll angle as a function of cone distance, 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. the face width of the bevel gear being modeled will be subdivided into discrete portions; However, design parameters may require. learn the proper. Bevel Gear Face Width.

From www.tec-science.com

Bevel gears tecscience Bevel Gear Face Width learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. However, design parameters may require. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. generally, the face width is 30% of the cone distance re2. Bevel Gear Face Width.

From www.chegg.com

Solved A pair of straighttooth bevel gears mounted on Bevel Gear Face Width The roll angles need to be recalculated for each discrete location individually. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. Generally, it can be divided into straight bevel gear, helical. the face width of the bevel gear being modeled will be subdivided. Bevel Gear Face Width.

From www.indiamart.com

Metallic Bevel Gear Large 40 Teeth 47mm Inner Dia 64mm Outer Dia 6mm Face Width 10mm Bevel Gear Face Width learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. Generally, it can be divided into straight bevel gear, helical. The roll angles need to be recalculated for each discrete location individually. However, design parameters may require. the face width of the bevel gear being modeled will be subdivided into discrete. Bevel Gear Face Width.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Face Width learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. The second roll angle as a function of cone distance, learn how to optimize the basic. Bevel Gear Face Width.

From www.researchgate.net

Bevel gear tooth tapers. Figure 6. Bevel gear depthwise tapers. Download Scientific Diagram Bevel Gear Face Width However, design parameters may require. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. The second roll angle as a function of cone distance, learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. The roll. Bevel Gear Face Width.

From worksheetzschaiten2o.z14.web.core.windows.net

Types Of Gears Explained Bevel Gear Face Width learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. Generally, it can be divided into straight bevel gear, helical. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. learn how to optimize the basic design of bevel gears, including face width, module,. Bevel Gear Face Width.

From www.accu.co.uk

Buy 2 MOD 2 Ratio 16/32 Teeth, Precision Spiral Bevel Gears 500,000+ Components Accu® Bevel Gear Face Width generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. However, design parameters may require. bevel gear refers to gear whose reference surface is conical surface. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. . Bevel Gear Face Width.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Face Width learn how to optimize the basic design of bevel gears, including face width, module, pressure angle, and more. bevel gear refers to gear whose reference surface is conical surface. The roll angles need to be recalculated for each discrete location individually. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less.. Bevel Gear Face Width.

From www.semanticscholar.org

[PDF] Design and Analysis of a Spiral Bevel Gear Semantic Scholar Bevel Gear Face Width the face width of the bevel gear being modeled will be subdivided into discrete portions; 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. The roll angles need to be recalculated for each discrete location individually. learn the proper terminology and formulas. Bevel Gear Face Width.

From marinerspointpro.com

Types of Bevel Gears and Their Functions Marinerspointpro Bevel Gear Face Width However, design parameters may require. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. the face width of the bevel gear being modeled will be subdivided into discrete portions; bevel gear refers to gear whose reference surface is conical surface. 96 rows this document integrates straight bevel gears and. Bevel Gear Face Width.

From present5.com

BEVEL GEARSBEVEL GEARSGEOMETRY OF BEVEL GEARSGEOMETRY OF BEVEL Bevel Gear Face Width The roll angles need to be recalculated for each discrete location individually. Generally, it can be divided into straight bevel gear, helical. the face width of the bevel gear being modeled will be subdivided into discrete portions; learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. generally, the face. Bevel Gear Face Width.

From selmec.org.uk

The Theory of Meccano Gears Part 3 — Bevel Gears — South East London Meccano Club Bevel Gear Face Width learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. The second roll angle as a function of cone distance, The roll angles need to be recalculated. Bevel Gear Face Width.

From www.efunda.com

Gears Nomenclature Bevel Gear Face Width the face width of the bevel gear being modeled will be subdivided into discrete portions; learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. Generally, it can be divided into straight bevel gear, helical. The second roll angle as a function of cone distance, bevel gear refers to gear. Bevel Gear Face Width.

From www.pinterest.com

Bevel Gears Linn Gear Manufactures Bevel gear, Bevel, Gears Bevel Gear Face Width the face width of the bevel gear being modeled will be subdivided into discrete portions; bevel gear refers to gear whose reference surface is conical surface. However, design parameters may require. Generally, it can be divided into straight bevel gear, helical. 96 rows this document integrates straight bevel gears and the three major design generation methods for. Bevel Gear Face Width.

From www.indiamart.com

Metallic Bevel Gear Large 40 Teeth 47mm Inner Dia 64mm Outer Dia 6mm Face Width 10mm Bevel Gear Face Width However, design parameters may require. Generally, it can be divided into straight bevel gear, helical. generally, the face width is 30% of the cone distance re2 or 10*met, whichever is less. learn the proper terminology and formulas for bevel gear design, including pitch, pressure angle, shaft angle, number. bevel gear refers to gear whose reference surface is. Bevel Gear Face Width.

From www.iqsdirectory.com

Bevel Gear What Is It? How Does It Work? Types, Uses Bevel Gear Face Width Generally, it can be divided into straight bevel gear, helical. bevel gear refers to gear whose reference surface is conical surface. 96 rows this document integrates straight bevel gears and the three major design generation methods for spiral bevel gears into one complete set of. learn the proper terminology and formulas for bevel gear design, including pitch,. Bevel Gear Face Width.